Sheet Lamination 3d Printer Cost Buy Additive Manufacturing

Some of the advantages of the sheet lamination process include low geometric distortion the original metal sheets retain their properties ease of making large scale 0 5 m 0 8 m 0 5 m parts relatively good surface finish and low cost.

Sheet lamination 3d printer cost buy additive manufacturing. Industrial metal 3d printer prices generally range from about 30 000 to over one million dollars for the most premium industrial grade metal additive manufacturing systems. Sheet lamination an additive manufacturing process in which sheets of material are bonded to form a part 1 sheet lamination can also be known as in alphabetical order. However sheet lamination does have some limitations. Metal 3d printer price.

Introduced to the market in the early 1990 s lom was the first commercially available sheet lamination process for additive manufacturing. A variety of processes equipment and materials are used in the production of a three dimensional object via additive manufacturing. Benefits include the use of a4 paper which is readily available and inexpensive as well as a relatively simple and inexpensive setup when compared to others. How much does a metal 3d printer cost.

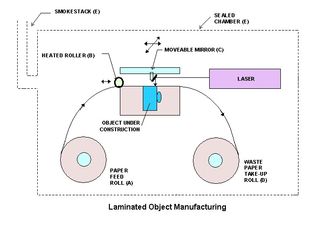

Laminated object manufacturing lom is a rapid prototyping system developed by helisys inc. The process is also called ultrasonic additive manufacturing uam in case the building material used. It was also one of the cheapest am processes at the time because parts were made by actually gluing sheets of paper together layer by layer. 3d printing is also known as additive manufacturing therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in the technologies and the materials used in this process.

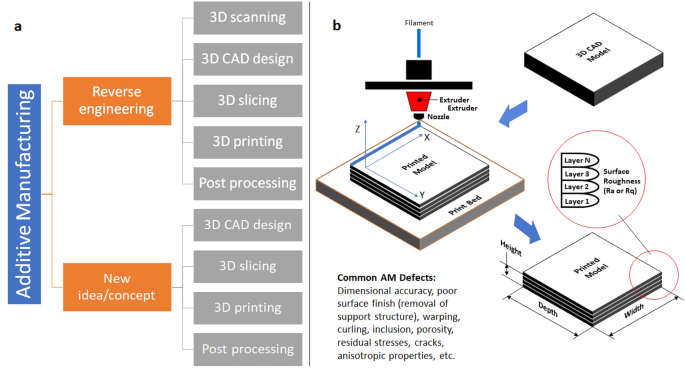

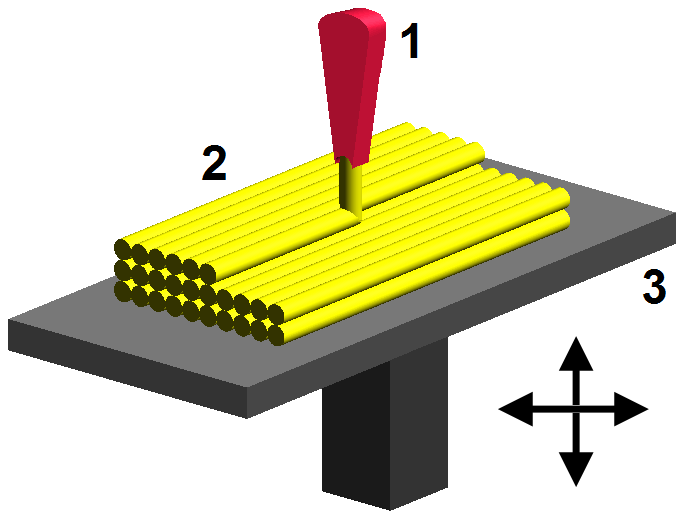

Laminated object manufacturing lom and ultrasonic consolidation uc are both examples of sheet lamination techniques. The sheet lamination sl 3d printing manufacturing technique also known as laminated object manufacturing lom consists of superpositioning several layers of material composed of foil in order to manufacture an object. Each foil is cut to shape with a knife or laser in order to fit to the object s cross section. The process uses sheets of building material which are cut through laser or knife and the sheets are joined one after the other either by using an adhesive or by wielding the laser cut sheets together to form the 3d object.

Computer aided manufacturing of laminated engineering materials or cam lem 2 laminated object manufacturing or lom 3. Sheet lamination is an additive manufacturing am methodology where thin sheets of material usually supplied via a system of feed rollers are bonded together layer by layer to form a single piece that is cut into a 3d object. Laminating lom is one of the first additive manufacturing techniques created and uses a variety of sheet material namely paper.